Fundamentals and Scope of the HACCP Approach

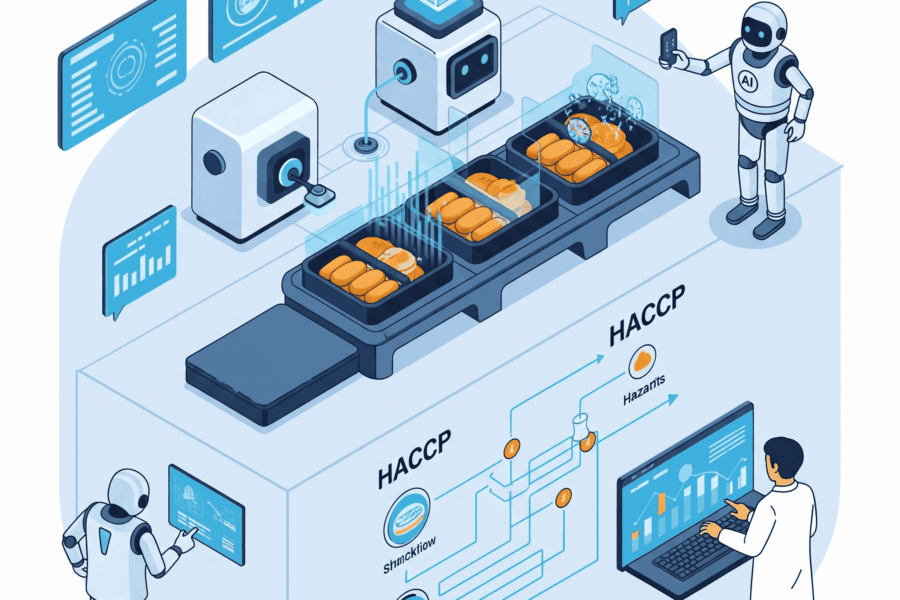

HACCP (Hazard Analysis and Critical Control Points) is a scientific and systematic method developed to ensure food safety. This system aims to identify potential hazards in food production processes and establish control mechanisms to prevent, eliminate, or reduce these hazards to acceptable levels.

Why Is the HACCP System Important?

At every stage of the food chain – production, processing, storage, distribution, and consumption – preventive measures must be implemented to ensure safety. HACCP is designed to proactively analyze and control risks before they lead to delays or irreversible mistakes.

The Seven Core Principles of HACCP

1. Hazard Analysis

Biological, chemical, and physical hazards are identified for each food product throughout the entire process from raw materials to the consumer.

2. Identifying Critical Control Points (CCPs)

Critical points in the process where identified hazards can be eliminated or minimized are determined.

3. Establishing Critical Limits

Measurable limits are set for each CCP to determine whether the control measures are effective.

4. Monitoring Procedures

Regular monitoring methods are defined to ensure each CCP remains under control.

5. Corrective Actions

Predefined corrective measures are planned in case a critical limit is exceeded.

6. Verification

Tests, inspections, and audits are conducted to verify the effectiveness of the system.

7. Documentation and Record-Keeping

All procedures and outcomes are documented to ensure traceability and system sustainability.

The 12 Implementation Steps of the HACCP System

- Assembling the HACCP team

- Describing the product

- Identifying intended use

- Constructing a process flow diagram

- On-site confirmation of the flow diagram

- Conducting hazard analysis and risk assessment

- Identifying critical control points

- Establishing critical limits

- Defining monitoring procedures

- Developing corrective actions

- Establishing verification procedures

- Maintaining documentation and records

HACCP Terminology: Key Concepts

- Hazard: Physical, chemical, or biological agents that may cause harm to food.

- Risk: The probability of a hazard occurring.

- Critical Control Point (CCP): Points where hazards are controlled.

- Critical Limit: The maximum or minimum acceptable value.

- Monitoring: Verifying that processes remain under control.

- Verification: Additional analyses and tests to ensure the system is effective.

- Corrective Action: Procedures implemented to resolve nonconformities.

Food Safety Policy and Management Responsibility

Top management is responsible for ensuring the effective implementation of the HACCP system across all processes. This includes:

- Defining the scope of implementation

- Establishing food safety objectives

- Ensuring system execution and sustainability at all levels

Conclusion

The HACCP system is an effective management tool that identifies food safety risks in advance and systematically controls them. It plays a vital role in ensuring regulatory compliance, customer satisfaction, and public health protection.